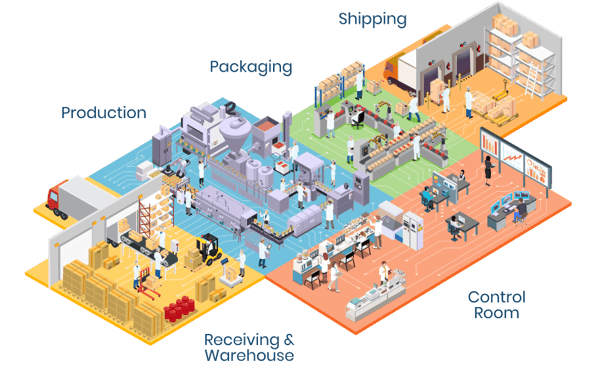

In Part 6 of our Demo Days series, we will demonstrate how SafetyChain's digital plant management platform captures and visualizes real-time and historical data to show the actual health of your plant.

No matter if you are an operator working on the line, or the President planning for new business, SafetyChain provides contextualized visibility to help you better manage and optimize any process throughout your plant.

SafetyChain's Demo Days is a series of 20 to 30 minute live demos showing common issues around manufacturing plants, and how SafetyChain's digital plant management platform helps solve for them through plant-wide data, insights, and tools.

Part 1: Receiving to Facility

Part 2: Sanitation & Start-Up Delays

Part 3: Production & Downtime Tracking

Part 4: Quality, SPC, & Post-Production Reviews

Part 5: Verifications & Shipping

Part 6: Business Tracking & Outcomes

Find out how SafetyChain is used to monitor and control critical functions like downtime tracking, regulatory programs, and supplier management.

.png?width=115&height=109&name=QMS%20(1).png)