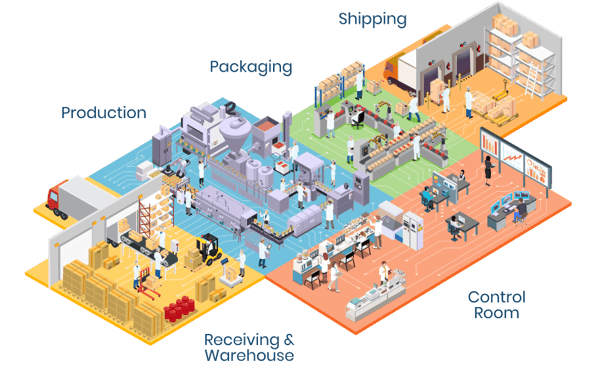

In part one of our Demo Days series we’ll zero in on receiving processes, showing examples of how SafetyChain prevents incidents and ensures compliance.

In this 30 minute demo you’ll see how operators use a mobile device to capture data in real-time (such as purchase order numbers, lot numbers, trailer numbers, and environmental conditions like temperature) during shipment delivery. You’ll also see how easy it is to flag non-conformances or deviations, and how quickly supervisors can view receiving records to identify exceptions.

Join us to hear real-world examples and see how SafetyChain empowers operators and supervisors with actionable insights to optimize plant operations and mitigate risks.

SafetyChain's Demo Days is a series of 20 to 30 minute live demos showing common issues around manufacturing plants, and how SafetyChain's digital plant management platform helps solve for them through plant-wide data, insights, and tools.

Part 1: Receiving to Facility

Part 2: Sanitation & Start-Up Delays

Part 3: Production & Downtime Tracking

Part 4: Quality & SPC

Part 5: Verifications & Shipping

Part 6: Business Tracking & Outcomes

Find out how SafetyChain is used to monitor and control critical functions like downtime tracking, regulatory programs, and supplier management.

.png?width=115&height=109&name=QMS%20(1).png)