In solving our paper problem we actually ended up solving a much bigger business problem with SafetyChain.

Tracy O., Corporate Applications Manager, HyLife Foods

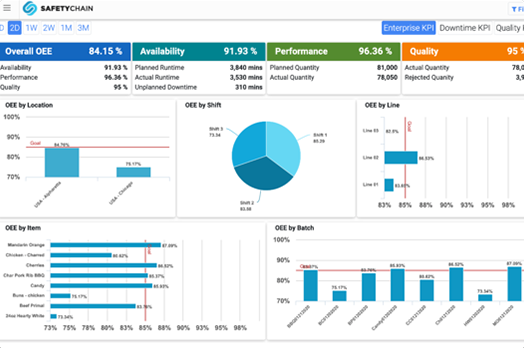

Monitor, trend, and report OEE data in real-time for every plant, line, and shift across the enterprise on customizable dashboards. Load production schedules, track actual to target performance and calculate dollars saved from reduced downtime and increased performance.

Utilize web, mobile, and floor-friendly production dashboards to actively monitor availability, performance, and root cause analysis across all your plants to help make better, faster operational decisions that drive continuous improvement.

Maximize yield

Reduce waste & rework